Table of Contents

What Is Nanomanufacturing and Why It Matters

Nanomanufacturing produces structures between 1 and 100 nanometers. At this scale, materials can behave differently. Strength, conductivity, and reactivity may shift. These shifts enable new devices and materials. Electronics, medicine, and energy benefit first. Traditional methods struggle to reach these sizes. Nanomanufacturing makes these outcomes practical.

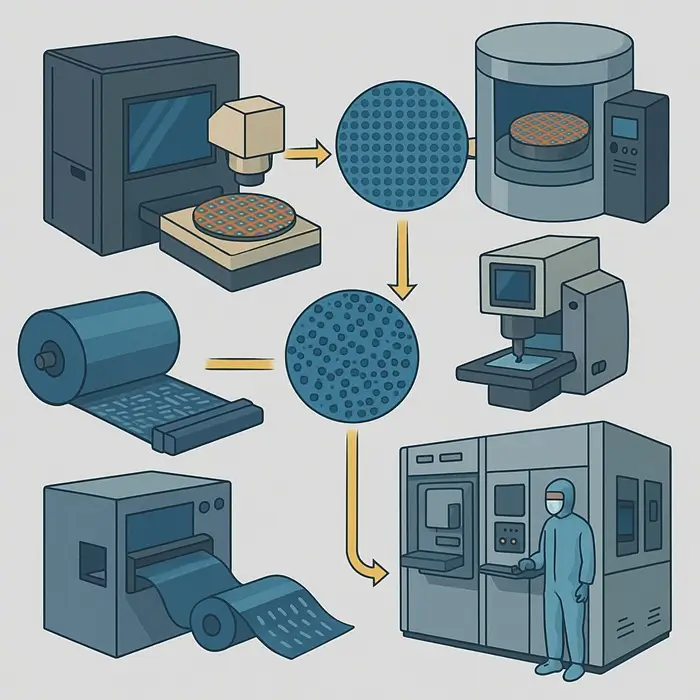

Top-Down vs Bottom-Up Nanomanufacturing

Nanomanufacturing uses two broad approaches. The right choice depends on design, cost, and scale.

Top-down

Start with bulk material and remove features.

-

Photolithography

-

Etching

-

Focused ion beam milling

Pros: high precision, mature in semiconductor lines.

Cons: more waste, limits on geometry.

Bottom-up

Build with atoms or molecules.

-

Self assembly

Pros: less waste, control at the atomic level.

Cons: scale up is hard, conditions are sensitive.

Core Techniques in Nanomanufacturing

Lithography

-

Photolithography: standard for microelectronics and many sensors.

-

Electron beam lithography: very fine features, low throughput.

-

Nanoimprint lithography: stamp patterns at scale with low cost per part. It routinely achieves sub-100 nm features at high throughput.

Thin-film and surface growth

-

Chemical vapor deposition: thin films, graphene, nanotubes, and coatings.

-

Atomic layer deposition: one layer at a time with precise thickness. Typical growth per cycle is about 0.8 to 1.5 angstroms, depending on chemistry.

-

Physical vapor deposition: sputtering and evaporation for metals and oxides.

-

Molecular beam epitaxy: ultra-pure epitaxial films for niche devices.

Wet and solution routes

First, sol gel forms oxide networks and low temperature coatings.

Additionally, colloidal lithography creates niche patterns for specific chemistries.

Likewise, dip pen lithography enables localized, chemistry driven feature writing.

Fibers and 3D forms

Self-assembly processes

First, use molecular forces to form ordered structures. Consequently, components self organize into predictable patterns. Additionally, this route supports bio interfaces and organic electronics. Therefore, it enables low energy, chemistry driven fabrication.

Process Physics: What Actually Controls Outcomes

First, nucleation and growth decide film quality. Early nuclei set grain size and texture. Moreover, surface energy and temperature set nucleation density. Therefore, precursors must adsorb, react, and desorb cleanly. Otherwise, side reactions add defects and roughness.

In ALD, each cycle has two self limiting half steps. Coverage should saturate each time. If not, incomplete saturation leaves pinholes. Conversely, overexposure can cause CVD like growth. As a result, roughness and stress rise.

Meanwhile, conformality matters on 3D features. Step coverage depends on sticking probability and mean free path. In practice, long pulses and proper purge improve sidewall dose. Likewise, low sticking increases conformality, although it can slow growth.

Finally, lithography has its own limits. Line edge roughness comes from photon shot noise and resist chemistry. In addition, focus and dose set critical dimension control. Post exposure bake sets diffusion and acid strength. During transfer, etch carries roughness into the film. Therefore, balance selectivity and profile control.

Integration and Thermal Budgets

First, every stack has a thermal budget. If exceeded, interfaces move. Consequently, diffusion blurs barriers and contacts. Therefore, choose chemistries that meet this budget. Whenever possible, use low-temperature routes.

Next, adhesion sits between layers. Thus, match surface energy carefully. When needed, add adhesion layers. Before deposition, clean the surface. Use plasma or wet cleans to strip organics and water. Otherwise, residuals cause voids and delamination.

Finally, plan the order of steps. Porous films should avoid wet chemistries unless closed. Likewise, fragile features need gentle drying. When possible, use supercritical or vapor phase drying.

Tools and Conditions Required

Effective nanomanufacturing needs tight control and good measurement. Cleanrooms for these steps often operate at ISO 5 to ISO 7 (ISO 14644 overview).

-

Cleanrooms: ISO classes with strict particle control.

-

Film metrology: ellipsometry vs XRR for thickness.

-

Surface chemistry: XPS basics with NIST guidance.

-

Automation: robotics for repeatable handling and placement.

-

AI and machine learning: optimize recipes and keep drift in check.

Further reading on metrology and QA: see our guides on ellipsometry versus XRR, AFM versus SEM

Metrology and Quality Control

Use in line gauges to control drift. Ellipsometry tracks thickness on monitor wafers. AFM samples roughness and feature height. SEM checks profile and defects.

Define acceptance ranges early. Tie each spec to function. Thickness, index, sheet resistance, and CD drive device yield. Add XRR for density and interface quality. Use XPS or Raman for chemistry and strain.

Run measurement system analysis. Gauge repeatability and reproducibility protect SPC. Bad gauges hide drift. Good gauges reveal trends fast.

Design experiments to map process windows. Change one factor at a time for quick checks. Use factorial designs for interactions. Lock center points for curvature checks.

Defects: Sources and Fixes

Applications Across Industries

Electronics and semiconductors

For electronics and semiconductors, applications include ultra-small transistors, interconnect barriers, and flexible conductors.

In addition, nanoscale memory devices increase density and speed. Likewise, advanced displays use nano-engineered pixels and thin films. Together, these advances cut power and enable new form factors.

Biotech and medicine

For biotech and medicine, applications include nanoparticle drug delivery, bioactive surfaces, and lab-on-a-chip platforms. In addition, antimicrobial and anti-fouling coatings reduce adhesion and infection risk. Moreover, these solutions enable targeted therapy and faster diagnostics. Together, they improve outcomes and device longevity.

Energy and environment

Advanced materials and coatings

For example, advanced materials include lightweight composites. In addition, hydrophobic and anti-corrosion layers protect surfaces. Likewise, thermal barriers improve heat resistance. Together, these coatings extend service life.

Scale Up and Throughput

Map lab to pilot with clear units. Report growth per cycle, dose, and purge. Also report resist dose, focus, and post-bake time. Record tool state and maintenance.

Pick the right scale path. Batch tools help films with long cycle times. Spatial ALD improves throughput for simple stacks. Roll to roll suits flexible webs. Nanoimprint shines for repeatable patterns. See a recent state-of-the-art review for industrial NIL status (2023 review).

Model cost per area. Include uptime, yield loss, and rework. A slow stable process can beat a fast unstable one.

Safety, Exposure, and Waste

Treat nanoparticles and reactive gases with care. Use closed tools and local extraction. Filter with HEPA or ULPA. Capture liquid and solid waste in sealed streams. Follow evidence-based guidance from NIOSH and OSHA (NIOSH lab guidance; NIOSH PtD 2018; OSHA factsheet).

Monitor exposure for key tasks. Weighing powders, tool opens, and waste swaps carry risk. Train staff. Keep logs. Review near misses.

Plan end of life for consumables. Spent resists, wipes, and filters can hold active species. Label and store with clear timings.

Cleanroom Practice and Contamination Control

First, people shed most particles. Therefore, gown correctly. Then, move slowly. Also, keep tools spaced to avoid cross drafts.

Next, control humidity and temperature. Resist and film chemistry depend on both. So, set clear ranges. Finally, alarm immediately when drift begins.

Meanwhile, segment dirty and clean flows. Do wet cleans away from open patterning. Additionally, use dedicated carts and boxes. Lastly, bake carriers to drive off water.

Design for Manufacturability at the Nanoscale

First, choose feature sizes with a margin. Avoid sitting at the tool limit. Next, add test structures to each mask. For example, place line-space arrays, contact chains, and Kelvin resistors.

Then, add process monitors in every run. Also, use scribe line pads for fast checks. Afterwards, the trend results over time. If trends break spec, stop and contain.

Current Challenges

-

Scale up: move from wafers to batch or roll to roll. Pilot first.

-

Standardization: set specs and test methods early with partners.

-

Reproducibility: use SPC, in line gauges, and design of experiments.

-

Health and safety: assess exposure, apply controls, and record waste flows.

Future Trends

-

Green nanotechnology: lower energy routes and safer chemistries.

-

AI driven production: adaptive control and predictive quality.

-

Quantum enabled devices: nanoscale stacks for quantum logic and sensing.

-

Nano robotics: precise placement and assembly at molecular scales.

Leave A Comment